140001环境管理证书 中文

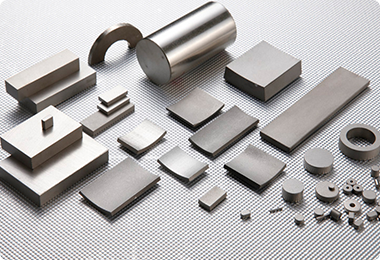

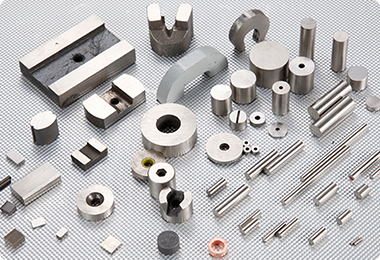

钕铁硼永磁

NdFeB是1983年以后发展起来的一种新型永磁材料,它具有极高的磁性能,广泛应用于各类永磁电机,工程机械、电声、电器及医疗器械等领域。

公司拥有VFS真空烧结炉、Alpine真空气流磨,氢破制粉及进口压机等先进设备,能生产N56、55M、55H、54SH、53UH、52EH等牌号的高性能NdFeB产品,年产量达3000吨。

工艺路线

生产设备

牌号总览

技术优势

体系认证

检测能力

产品应用

工艺路线

-

熔炼炉

-

气流磨

-

成型压机

-

烧结炉

-

打孔机

-

多线切割机

牌号总览

牌号系列

| Material 类别 |

GB/T 13560-2017 Nomenclature 规定牌号 |

Grade 牌号 |

Parameters 性 能 | ||||||

| Br 剩磁感应强度 |

Hcb 矫顽力 |

Hcj 内禀矫顽力 |

(BH)max 最大磁能积 |

∣Temperture Coefficient∣ 温度系数 |

Tw 最高工作温度 |

||||

| mT(kGs) | kA/m(kOe) | kA/m(kOe) | kJ/m3(MGOe) | ∣αBr∣ %/℃ | ∣βHcj∣ %/℃ | ℃ | |||

| N | S-NdFeB 280/96 | N35 | 1180-1230 (11.8-12.3) | ≥876 (≥11) | ≥955 (≥12) | 263-287 (33-36) | 0.10-0.124 | 0.65-0.80 | 80 |

| S-NdFeB 300/96 | N38 | 1230-1260 (12.3-12.6) | ≥899 (≥11.3) | ≥955 (≥12) | 287-310 (36-39) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 320/96 | N40 | 1260-1290 (12.6-12.9) | ≥912 (≥11.5) | ≥955 (≥12) | 302-326 (38-41) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 335/96 | N42 | 1290-1330 (12.9-13.3) | ≥923 (≥11.6) | ≥955 (≥12) | 318-342 (40-43) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 360/96 | N45 | 1330-1370 (13.3-13.7) | ≥931 (≥11.7) | ≥955 (≥12) | 342-366 (43-46) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 380/96 | N48 | 1370-1400 (13.7-14.0) | ≥939 (≥11.8) | ≥955 (≥12) | 366-390 (46-49) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 400/96 | N50 | 1390-1430 (13.9-14.3) | ≥947 (≥11.9) | ≥955 (≥12) | 374-406 (47-51) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 415/96 | N52 | 1420-1460 (14.2-14.6) | ≥947 (≥11.9) | ≥955 (≥12) | 390-414(49-52) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 430/96 | N54 | 1450-1490 (14.5-14.9) | ≥912 (≥11.5) | ≥955 (≥12) | 406-438 (51-55) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 445/96 | N56 | 1480-1520 (14.6-15.2) | ≥860 (≥10.8) | ≥876 (≥11) | 422-454 (52-57) | 0.10-0.124 | 0.65-0.80 | 70 | |

| M | S-NdFeB 280/111 | 35M | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1114 (≥14) | 263-287 (33-36) | 0.10-0.124 | 0.60-0.75 | 100 |

| S-NdFeB 300/111 | 38M | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1114 (≥14) | 287-310 (36-39) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 320/111 | 40M | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1114 (≥14) | 302-326 (38-41) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 335/111 | 42M | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1114 (≥14) | 318-342 (40-43) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 360/111 | 45M | 1330-1370 (13.3-13.7) | ≥1002 (≥12.6) | ≥1114 (≥14) | 342-366 (43-46) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 380/111 | 48M | 1370-1400 (13.7-14.0) | ≥1027 (≥12.9) | ≥1114 (≥14) | 366-390 (46-49) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 400/111 | 50M | 1390-1430 (13.9-14.3) | ≥1035 (≥13.0) | ≥1114 (≥14) | 374-406 (47-51) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 415/111 | 52M | 1420-1460 (14.2-14.6) | ≥995 (≥12.5) | ≥1114 (≥14) | 390-414 (49-52) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 430/111 | 54M | 1450-1490 (14.5-14.9) | ≥995 (≥12.5) | ≥1114 (≥13) | 406-438 (51-55) | 0.10-0.124 | 0.60-0.75 | 90 | |

| H | S-NdFeB 240/135 | 30H | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1353 (≥17) | 223-247 (28-31) | 0.09-0.120 | 0.55-0.70 | 120 |

| S-NdFeB 260/135 | 33H | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1353 (≥17) | 247-271 (31-34) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 280/135 | 35H | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1353 (≥17) | 263-287 (33-36) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 300/135 | 38H | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1353 (≥17) | 287-310 (36-39) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 320/135 | 40H | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1353 (≥17) | 302-326 (38-41) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 335/135 | 42H | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1353 (≥17) | 318-342 (40-43) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 360/135 | 45H | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1353 (≥17) | 342-366 (43-46) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 380/135 | 48H | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1353 (≥17) | 366-390 (46-49) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 400/135 | 50H | 1390-1430 (13.9-14.3) | ≥1058 (≥13.3) | ≥1353 (≥17) | 374-406 (47-51) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 415/127 | 52H | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1353 (≥17) | 390-417 (49-52) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 430/127 | 54H | 1450-1490 (14.5-14.9) | ≥1074 (≥13.5) | ≥1274 (≥16) | 406-438 (51-55) | 0.09-0.120 | 0.55-0.70 | 110 | |

| SH | S-NdFeB 240/159 | 30SH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1592 (≥20) | 223-247 (28-31) | 0.09-0.120 | 0.50-0.65 | 150 |

| S-NdFeB 260/159 | 33SH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1592 (≥20) | 247-271 (31-34) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 280/159 | 35SH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1592 (≥20) | 263-287 (33-36) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 300/159 | 38SH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1592 (≥20) | 287-310 (36-39) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 320/159 | 40SH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1592 (≥20) | 302-326 (38-41) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 335/159 | 42SH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1592 (≥20) | 318-342 (40-43) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 360/159 | 45SH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1592 (≥20) | 342-366 (43-46) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 380/159 | 48SH | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1592 (≥20) | 366-390 (46-49) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 400/159 | 50SH | 1390-1430 (13.9-14.3) | ≥1058 (≥13.3) | ≥1592 (≥20) | 374-406 (47-51) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 415/159 | 52SH | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1512 (≥19) | 390-414 (49-52) | 0.09-0.120 | 0.50-0.65 | 140 | |

| UH | S-NdFeB 220/199 | 28UH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥1990 (≥25) | 207-231 (26-29) | 0.09-0.110 | 0.50-0.60 | 180 |

| S-NdFeB 240/199 | 30UH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1990 (≥25) | 223-247 (28-31) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 260/199 | 33UH | 1140-1180 (11.4-11.8) | ≥827 (≥10.4) | ≥1990 (≥25) | 247-271 (31-34) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 280/199 | 35UH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1990 (≥25) | 263-287 (33-36) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 300/199 | 38UH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1990 (≥25) | 287-310 (36-39) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 320/199 | 40UH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1990 (≥25) | 302-326 (38-41) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 335/199 | 42UH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1990 (≥25) | 318-342 (40-43) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 360/199 | 45UH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1990 (≥25) | 342-366 (43-46) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 380/199 | 48UH | 1360-1400 (13.6-14.0) | ≥1035 (≥13.0) | ≥1910 (≥24) | 358-390 (45-49) | 0.09-0.110 | 0.50-0.60 | 170 | |

| EH | S-NdFeB 220/239 | 28EH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2388 (≥30) | 207-231 (26-29) | 0.09-0.110 | 0.45-0.55 | 200 |

| S-NdFeB 240/239 | 30EH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2388 (≥30) | 223-247 (28-31) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 260/239 | 33EH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2388 (≥30) | 247-271 (31-34) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 280/239 | 35EH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2388 (≥30) | 263-287 (33-36) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 300/239 | 38EH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥2388 (≥30) | 287-310 (36-39) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 320/239 | 40EH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥2388 (≥30) | 302-326 (38-41) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 335/239 | 42EH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥2388 (≥30) | 318-342 (40-43) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 360/231 | 45EH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥2308 (≥29) | 342-366 (43-46) | 0.09-0.110 | 0.45-0.55 | 190 | |

| TH | S-NdFeB 220/279 | 28TH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2786 (≥35) | 207-231 (26-29) | 0.09-0.110 | 0.40-0.50 | 230 |

| S-NdFeB 240/279 | 30TH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2786 (≥35) | 223-247 (28-31) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 260/279 | 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 280/279 | 35TH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2786 (≥35) | 263-287 (33-36) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 300/279 | 38TH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥2786 (≥35) | 287-310 (36-39) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 320/279 | 40TH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥2786 (≥35) | 302-326 (38-41) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 335/270 | 42TH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥2706 (≥34) | 318-342 (40-43) | 0.09-0.110 | 0.40-0.50 | 220 | |

加工能力

电镀镀层

体系证书

140001环境管理证书 英文

IATF16949证书 中文

IATF16949证书 英文

ISO9001证书 中文

ISO9001证书 英文

振泽知识产权证书

成分检测

ICP 光普分析仪

碳硫分析仪

氧氢分析仪

磁性能检测

磁滞回线测量仪

EF14磁矩

HT707测试仪

磁偏角测试仪

磁性能测试仪

表磁测试仪

尺寸外观检测

尺寸外观缺陷全检机

可靠性检测

尺寸分选机

电子万能试验机

镀层测厚仪

高度加速寿命试验箱

冷热冲击试验箱

投影仪

显微镜

盐雾

三坐标测试仪

轮廓仪

粒度测试仪

电阻率测试仪

产品展示

应用领域